These temperature sensors are designed for precise temperature measurement. They convert the physical quantity temperature into an electrical signal and impress with their high signal stability even under extreme conditions.

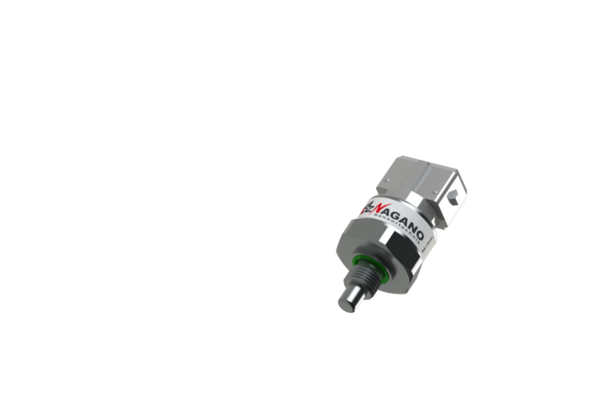

Ideal for applications that require simultaneous monitoring of pressure and temperature, these pressure and temperature sensors an integrated solution that saves space and costs.

Temperature switches are essential for overheating protection and other safety functions. They switch accordingly predefined temperature limits to prevent damage and failures.